After research and successfully launch the permeable paver product in Q4 2023, Hoang Son and Eco System continue to develop this product line with materials from construction debris.

Mr. Takata Mimoru, Development Director of Eco System shared that every year in Japan, thousands of houses must be dismantled due to its characteristics such as old, damaged, outdated and unsafe, or earthquakes. Therefore, there is a significant quantity of construction debris including steel, concrete, gypsum board, wood, etc. must be treated. Furthermore, Japanese government do not allow exploitation of natural resources, especially sand, stone, gypsum to construct new houses and require households to recycle most of old materials. For example, steel is collected and recycled at steel factories and reused for new houses, gypsum board is crushed, paper content is separated and recycled to new gypsum board. Similarly, concrete debris is also crushed, classified and recycled in brick and concrete production.

In Vietnam, construction debris, especially concrete debris are used for landfill purpose of small/medium sized projects. As natural resources such as sand, stone in Vietnam is still available and the cost is reasonable, not many companies research and invest in recycled materials for production.

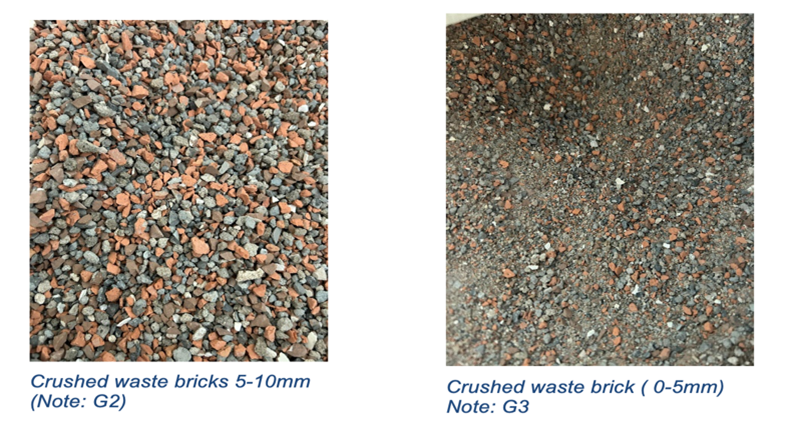

Regarding recycled materials, CC Innovation Vietnam Co., Ltd, a business partner of Eco System in Vietnam invested a lot of time and effort to find a company who specializes in crushing and classifying debris without any success after months. Afterwards, they decided to buy the debris and hire 3rd party to crush and classify debris following their instructions. Some examples on output:

With the above recycled materials acquired, Eco System and Hoang Son started to experiment with 05 different trial mix to produce permeable paver from recycled materials. Besides debris, we also use Song Hau 1 fly ash in the mix design to produce paver, which reduce CO2 emission in clinker and cement grinding production.

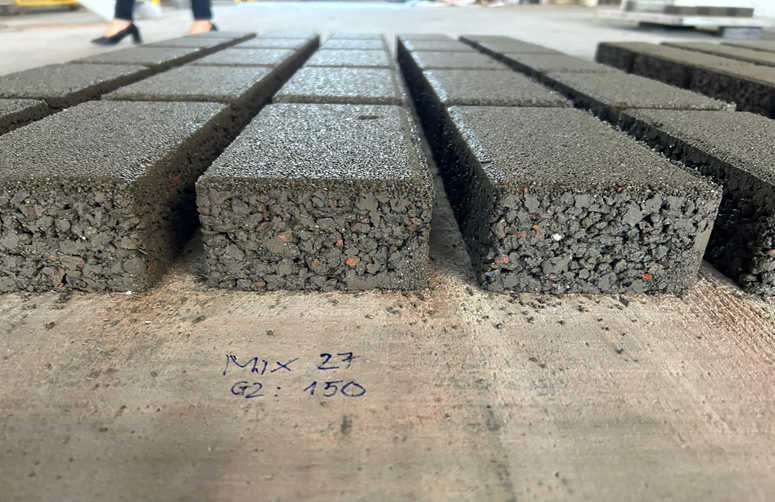

With positive results in the lab of all five trial mix, we continue to produce in our machinery. The difference between lab result and actual production caused us with many difficulties, such as the classification of recycled material for mass production, cleaning method for material funnel, weighting and moisture of recycled material, and half-dried concreted mixed with recycled material run into conveyor and mold, etc. Thanks to our experience and knowledge from experts, we tried our best to manage the above issues, resulted in relatively high-quality products after first production. We are waiting for R7 and R28 testing result to conclude on feasibility of using recycled debris for permeable paver production.

By the end of August this year, Eco System and Hoang Son expect to deliver the products to Aeon Mall Tan Phu construction project. The investor agreed to use permeable paver from recycled materials for parking area. We will update on the product after being put into use at project site and tested by Japanese expert on paver’s temperature and water absorption and compared with other ordinary ziczac paver.