As of 2030, Vietnam has nearly 30 coal-fired power plants of various sizes stretching from the North to the South. Most coal-fired power plants in the North were constructed with older technology, supported and operated with assistance from Chinese constructors. The primary fuel for these plants is domestic anthracite coal. In contrast, coal-fired power plants in the Central and Southern regions mostly employ modern, environmentally friendly technologies, being newly constructed, and some use imported coal. The total coal consumption for these power plants is approximately 50 million tons per year, resulting in around 16 million tons of fly ash and bottom ash emissions annually.

Challenges in Fly Ash Utilization

- Quality:

Most coal-fired power plants in Vietnam burn domestic anthracite coal and bituminous coal imported from Australia, Indonesia, or South Africa. Anthracite coal has high calorific heat value but is hard and difficult to burn, with an ash content of up to 20%. Therefore, coal-fired plants using domestic coal usually have large ash landfill sites (5–10 million m³), with an average ash output of around 1.2 million tons per year. Fly ash from anthracite coal is Class F, gray in color, with 8–10% loss on ignition, and an average fineness (Residue on sieve 45 micron) of 25%, meeting Vietnamese standards (TCVN 12249:2018). However, this ash does not meet export standards under ASTM C618 (<6% LOI) and EN 450-1 (<5% LOI, fineness <12%). Anthracite fly ash is popular domestically due to its gray color similar to cement, which minimally affects the aesthetics of cement or concrete. Its reactivity with OPC cement is moderate (R7: 70–75%, R28: 80–85%), so ready-mix concrete plants in Ho Chi Minh City generally use less than 20% of total binder content to ensure consistent quality.

Southern coal-fired power plants (from Khanh Hoa to Ca Mau): Most of these plants were built within the last 5–10 years, utilizing modern technology and imported bituminous coal. Bituminous coal is soft, easy to burn, and has good calorific heat value, resulting in low fly ash production (around 250,000 tons/year). Bituminous fly ash is also Class F, light brown in color, with only 1% loss on ignition, and an average fineness (Residue on sieve 45 micron) of 25%. The brown ash has slightly higher reactivity with cement than gray anthracite ash but still does not meet ASTM C618 and EN 450-1 standards. Previously, its color was a major drawback; however, since 2020, with the emergence of Ground granulated blast furnace slag (white, also used as a clinker and OPC cement substitute), the market has gradually accepted brown fly ash.

- Quantity supplied:

Coal-fired power accounts for 40–50% of Vietnam’s total installed power capacity up to the present. The electricity generation sequence prioritizes: hydro, renewable energy (wind, solar), liquefied natural gas (LNG), and lastly coal due to cost considerations and environment. In Southern Vietnam, there are two main seasons: dry (February–August) and rainy (September–January). During the rainy season, hydro is prioritized, and coal-fired plants operate at low capacity, reducing fly ash production to 30–40% of the dry season output. Meanwhile, Q3–Q4 is the peak season for construction materials, causing supply-demand mismatch. Concrete plants must adjust mix designs, increasing cement content to compensate for reduced fly ash, resulting in higher CO₂ emissions and production costs. Conversely, in the dry season, coal plants operate at high load, fly ash is abundant, but demand is low, forcing plants to moisten 30–40% of unconsumed fly ash for storage at landfill.

Hoang Son’s solution

Hoang Son is a pioneering company in the fly ash sector in the Southern Vietnamese market. Since 2015, we have introduced Duyen Hai fly ash in Ho Chi Minh City, while also investing in silos and providing technical consultancy to concrete plants to demonstrate the benefits and utilize fly ash in production. With over 20 years of experience in the construction materials industry, 10 years in fly ash consumption and management, and the support of experts from EPPM Europe, Hoang Son has developed solutions that ensure consistent quality and stable supply for our customers.

Quality Solution – Hoang Son Ultra Fine Fly Ash:

- The finer the fly ash, the higher its reactivity with OPC cement.

- R28 reactivity > 100% per ASTM C618, exceeding Vietnamese, US, and EU standards.

- Early strength: R3 = 94.1%, R7 > 95%, significantly higher than raw fly ash, easier concrete workability, less heat generation, and increased durability.

- Allows higher substitution of fly ash in total binder content, reducing cement usage, lowering CO₂ emissions, saving costs, and providing economic and environmental benefits.

Physical properties: Ultra fine fly ash

| Criteria | Standard index | Note | ASTM C618 | EN 450-1 | TCVN |

| Blaine fineness (specific surface area) | 8.000 – 12.000 cm²/g | Regular fly ash: 3.000–5.000 cm²/g | N/A | N/A | N/A |

| Residue on 45-µm sieve | < 5% (normally < 1%) | Very high fineness | ≤ 34.0 % | Category N (Normal): ≤ 40% Category S (Mịn): ≤ 12% | ≤ 25.0 % |

| Bulk density | 800 – 1.000 kg/m³ | Depending on carbon content and grinding method | N/A | N/A | N/A |

| Loss on ignition (LOI) | < 3% (normally < 1,5%) | Low LOI | ≤ 6.0% | Category A: ≤ 5,0% Category B: ≤ 7,0% Category C: ≤ 9,0% | ≤ 12.0% |

| Moisture | < 0,5% | Ensures pneumatic transportability | ≤ 3.0% | N/A | ≤ 3.0% |

| Pozzolanic activity index (28 days) | > 100% compared to the reference cement sample | Following ASTM C311 | ≥ 75.0% | ≥ 75.0% | ≥ 75.0% |

| Colour | Light grey to medium grey | Depends on coal | N/A | N/A | N/A |

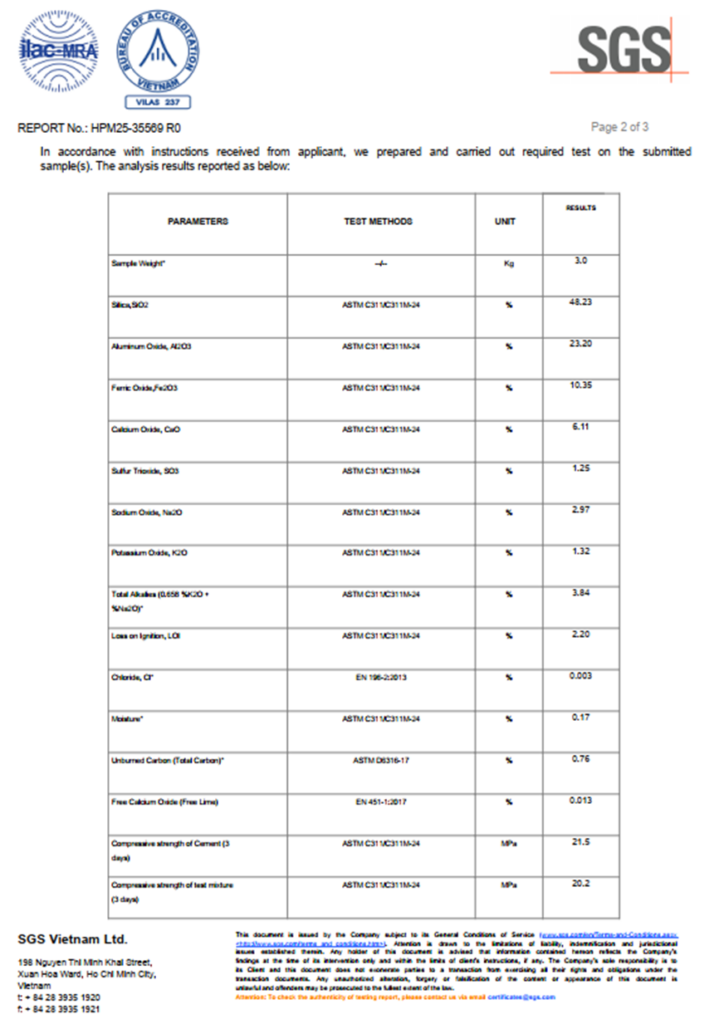

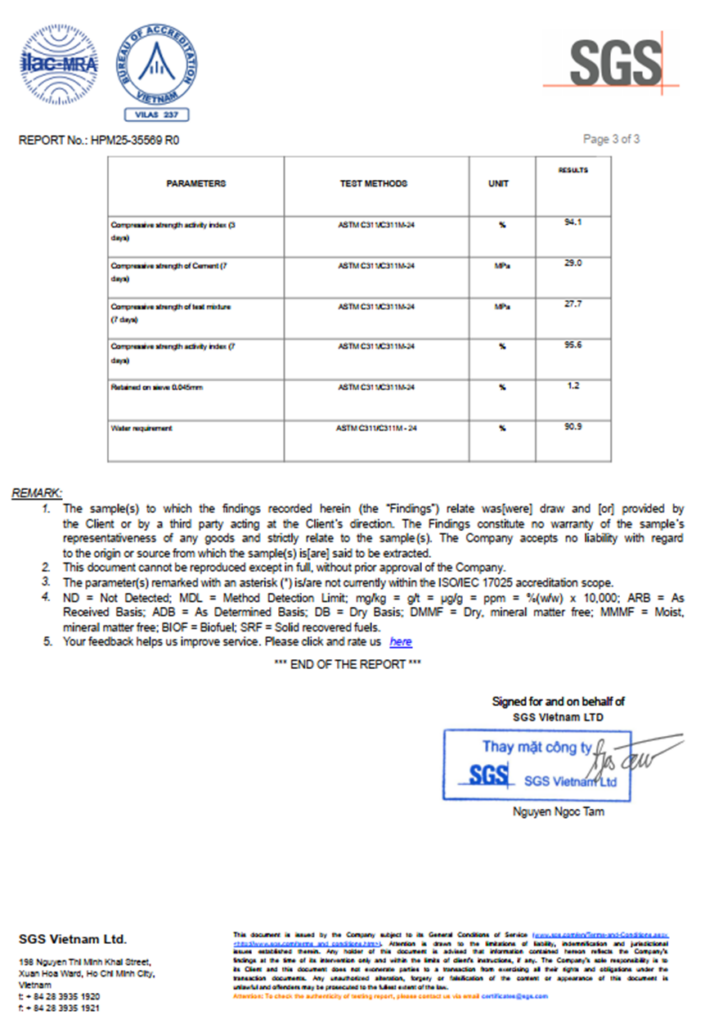

Chemical properties: Ultra fine fly ash

| Item | Content (%) | Note | ASTM C618 | EN 450-1 | TCVN |

| SiO₂ | 55 – 65 | Plays a key role in the pozzolanic reaction | |||

| Al₂O₃ | 25 – 30 | Enhanced activity | (SiO₂ + Al₂O₃ + Fe₂O₃ ) ≥ 70% | (SiO₂ +Al₂O₃ +Fe₂O₃ ) ≥ 70% | (SiO₂ +Al₂O₃ +Fe₂O₃ ) ≥ 70% |

| Fe₂O₃ | 4 – 8 | Depending on coal | |||

| CaO | < 5 | Low, characteristic of Type F | < 10.0 % | < 10.0 % | < 10.0 % |

| MgO | < 2 | – | N/A | ≤ 4,0% | N/A |

| SO₃ | < 2 | Following ASTM C618 | ≤ 5.0% | ≤ 3,0% | ≤ 3,5% |

| Na₂O + K₂O | < 1,5 | Reduces the risk of alkali–silica reaction (ASR) | N/A | ≤ 5.0 % | ≤ 1,5% |

| Loss on ignition (LOI) | < 3 | Low LOI content | ≤ 6.0 % | Category A: ≤ 5,0% Category B: ≤ 7,0% Category C: ≤ 9,0% | ≤ 12.0 % |

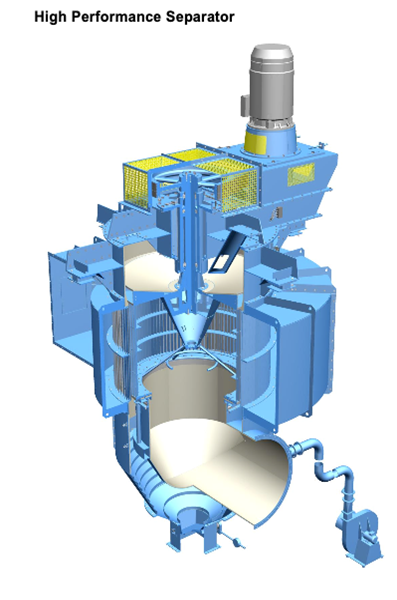

Production Solution – Hoang Son Fly Ash Processing Plant:

- Strong plant capacity and infrastructure ensure a stable supply, minimizing risks from weather, rainy season, and coal fire power plant maintenance or shutdowns.

- Provides a consistent supply to strategic customers, meeting market demand year-round.

Introduction to Hoang Son Fly Ash Processing Plant:

- Location: Long Hau Industrial Park, Can Giuoc Ward, Tay Ninh Province, 30 minutes travelling south of Ho Chi Minh City.

- Port: 120m long pier, capable of receiving vessels up to 3,000 tons.

- Pumping system: closed-loop, no direct environmental exposure, weather-resistant.

- Design & equipment: Christian Pffier (Germany)

- Bucket elevator system: Beumer (Germany), Tanker discharge telescope: Ibau (Germany)

- Steel structure contractor: Dai Dung III.

- Capacity: 900,000 tons/year.

- Finished product silos: 12,000 tons (Phase 1: 4,000 tons, Phase 2: 8,000 tons).

- Certifications: ISO, green factory.

- Personnel: professionally trained by EPPM Europe.